Our Services

We develop scientific equipment through every phase of development—from concept to production. Some customers come to us with a rough idea and work with us through to a finished tool; others bring us in to solve a more specific and bounded problem within a larger effort—like machining a part, designing a subcomponent, or refining the usability of an interface.

Our customers mostly work with us in one of three ways:

Contract R&D

We work with research groups, innovators, and educators to develop tools and equipment tailored to your work. You define the challenge and contribute your field-specific knowledge; we act as an embedded product development team—bringing strategy, design, engineering, prototyping, testing, and manufacturing expertise. Through this close collaboration, we build powerful, precise, and beautiful equipment that helps you do your work better.

We can contract on hourly or project terms, depending on the nature and scale of the work. We can also work on a retainer basis—often tied to grant funding cycles—whereby labs secure dedicated access to our team before specific project needs are defined, so we're ready to move quickly as new ideas emerge.

To support early-stage development, we include machining hour credits in our contract R&D work—helping reduce the cost of prototyping as ideas take shape.

Co-commercialization

Some projects are better suited to a shared model. When a tool has broader potential and traditional funding is limited, we often invest our own time and resources into the R&D—taking the lead on engineering, design, prototyping, and production. You contribute domain expertise and testing insight; we guide the development process and carry it through to a finished, manufacturable tool.

Instead of billing for the full cost of development, we share ownership of the resulting IP and bring the tool to market ourselves. Once it’s in production, we share revenue with you through royalties.

This model is a simple way to turn field-proven ideas into widely available tools—without requiring you to manage manufacturing or commercialization.

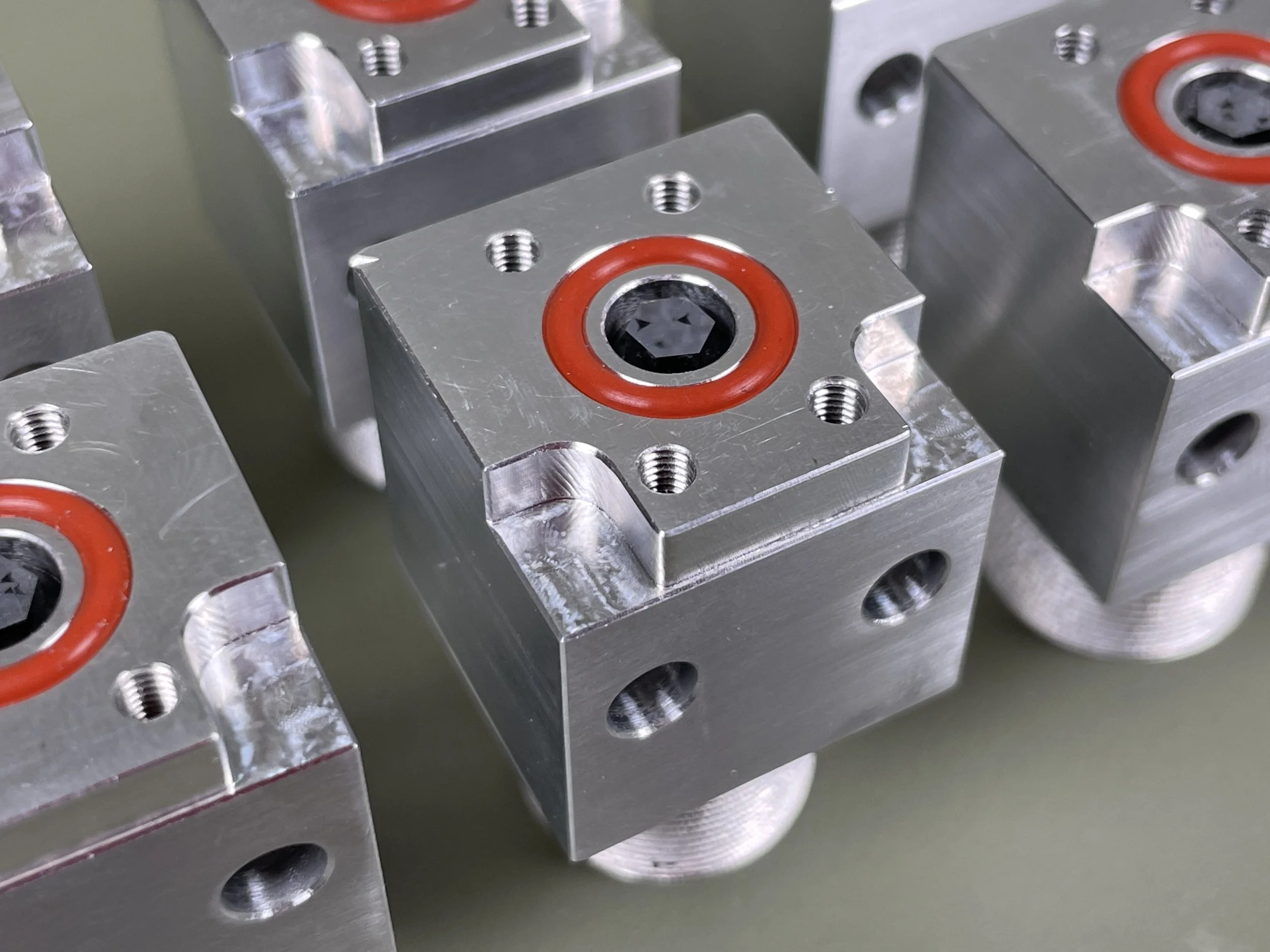

Contract Manufacturing

We provide specialist small-batch manufacturing for the science sector. We focus on tight-tolerance parts, complex assembly processes, micro-machining, and fabrication workflows that require adaptation, testing, or iteration. In other words, the kind of work that’s often too involved—or carries too many unknowns—for conventional shops to take on.

Our shop is built for the demands of scientific work. We’re equipped with high-end CNC machine tools for precise and repeatable machining and micro-machining. Alongside that, we bring journeyman skills in high-precision manual machining, grinding, lapping, and finishing—expertise that complements what modern machines can do. This combination allows us to adapt to unusual materials, complex geometries, and the highly specific measurement requirements that come with manufacturing for science.

Working with us means short feedback loops, consistent quality, and a team that understands how the parts we make are actually used.

Let’s talk

Not sure where your project fits?

We’re happy to talk through your needs—whether it’s a rough idea, a prototype, or just a sketch on paper.